SIF-400 - Training system for Industry 4.0

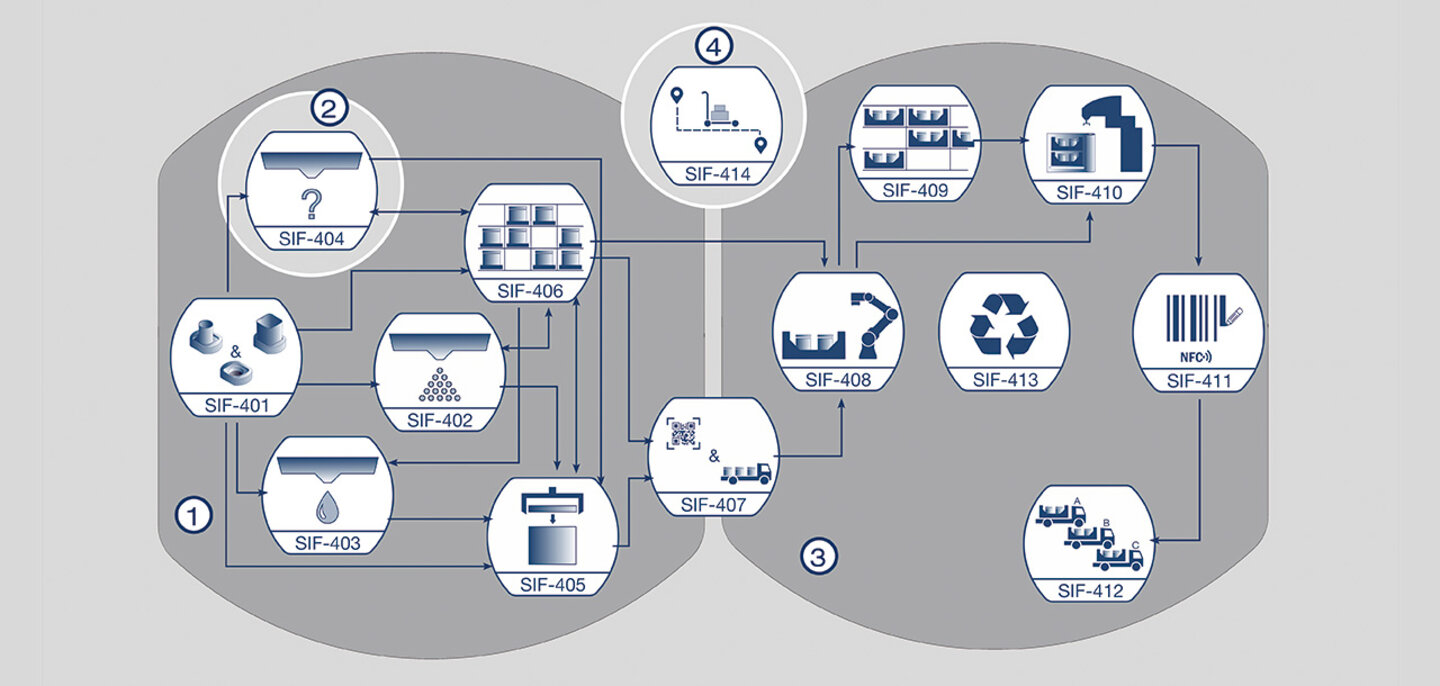

The SIF-400 training system simulates a highly automated smart factory, including Industry 4.0 technologies, advanced manufacturing concepts and the reality of the connected enterprise.

The SIF-400 training system simulates a highly automated smart factory, including Industry 4.0 technologies, advanced manufacturing concepts and the reality of the connected enterprise.

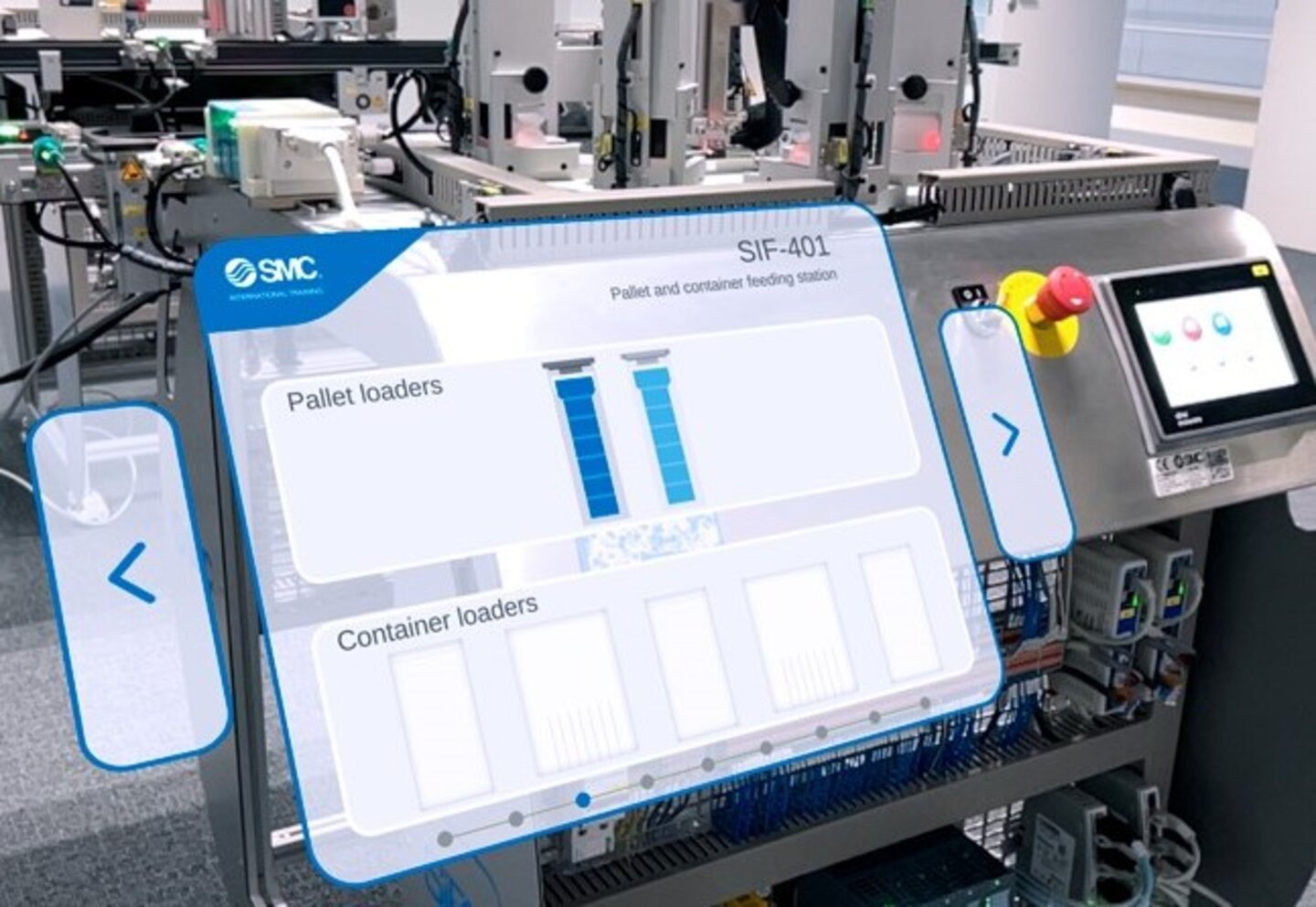

SIF-400, a training system designed to give you the most complete and advanced experience in the world of industrial automation, as it emulates the real processes of a highly automated factory. All the components in SIF-400 are used in industry, so that user can work with real elements at all times making the learning process more meaningful.

SIF-400 training system is being designed to help develop the skills in INDUSTRY 4.0 TECHNOLOGIES. It emulates a highly automated smart factory that includes different Industry 4.0 technologies with which users can be trained for real world. The user will be able to be trained and develop skills in Industry 4.0 technologies such as: Industrial Management Software Systems (MES, ERP), OPC UA, Web Services, identification systems (RFID, QR, NFC & BCR), collaborative robots, artificial vision, smart devices (IO-link), among many others, to acquire the skills required by the industry of the future.

Image gallery