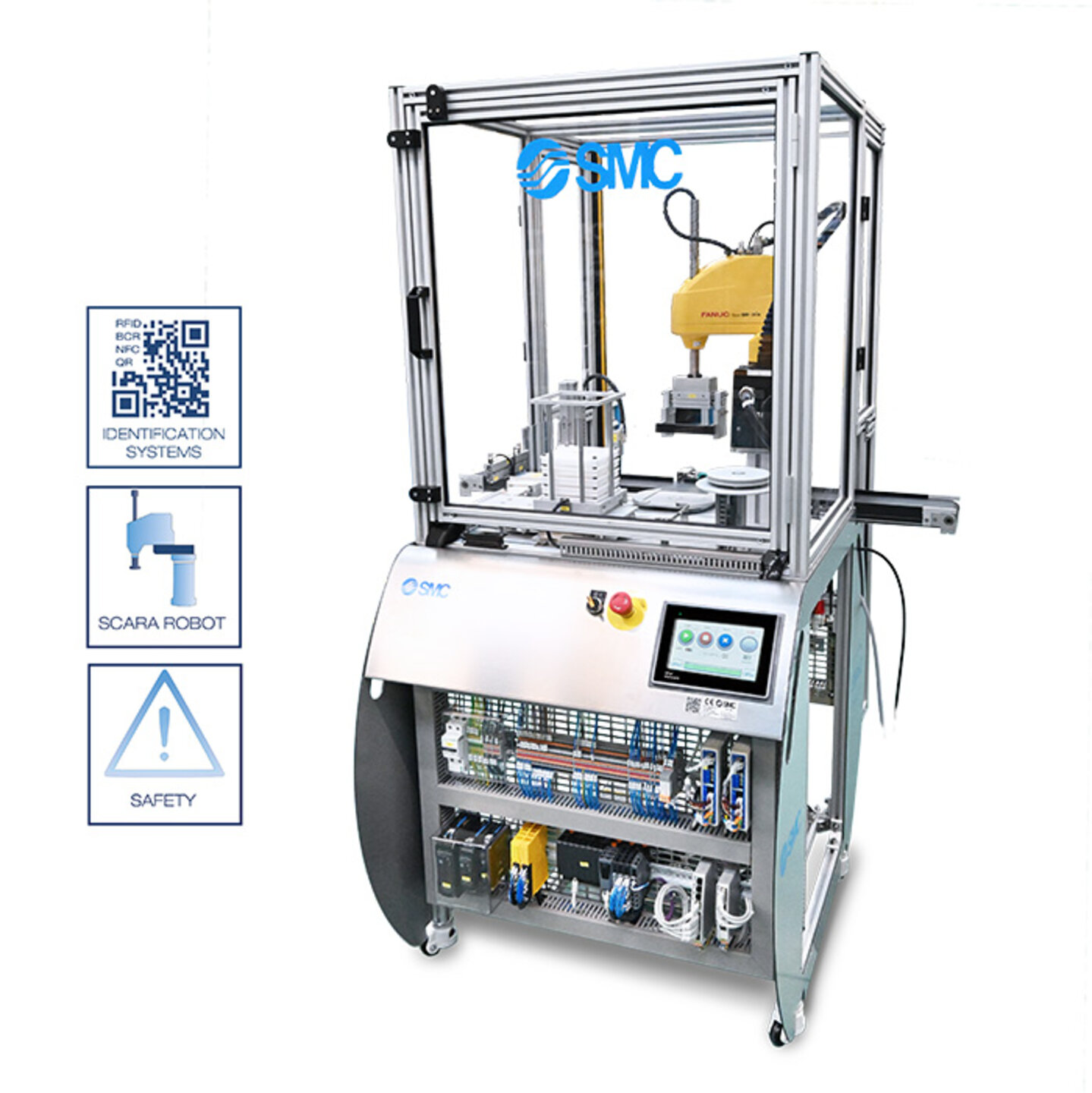

SIF-400 Stations

Each of the SIF-400 system stations carries out part of the process. Know more about the process carried out by each of the station and the specific technologies in each station.

Each of the SIF-400 system stations carries out part of the process. Know more about the process carried out by each of the station and the specific technologies in each station.

Choose the option that best suits your needs and discover how to order.