Real industrial assembly

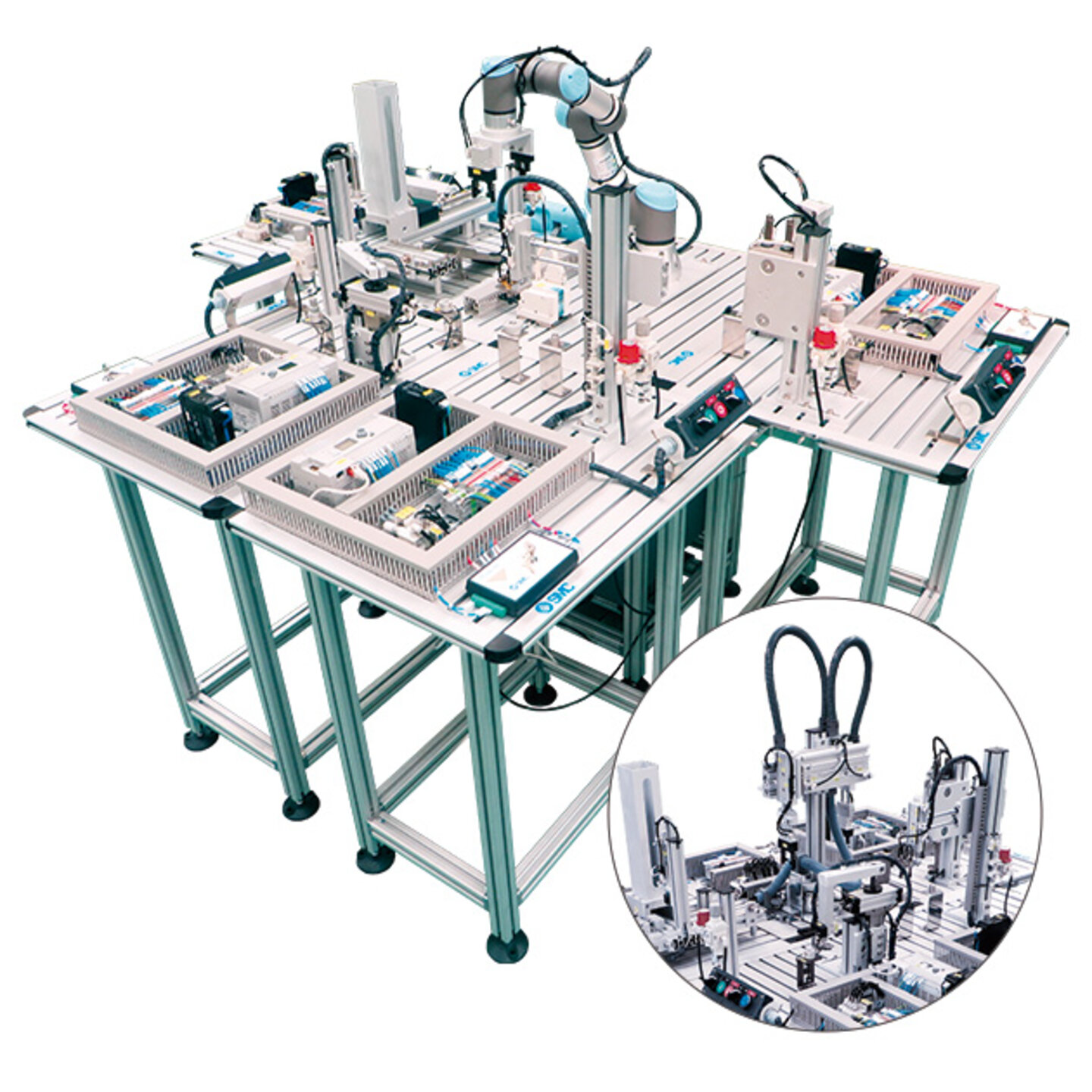

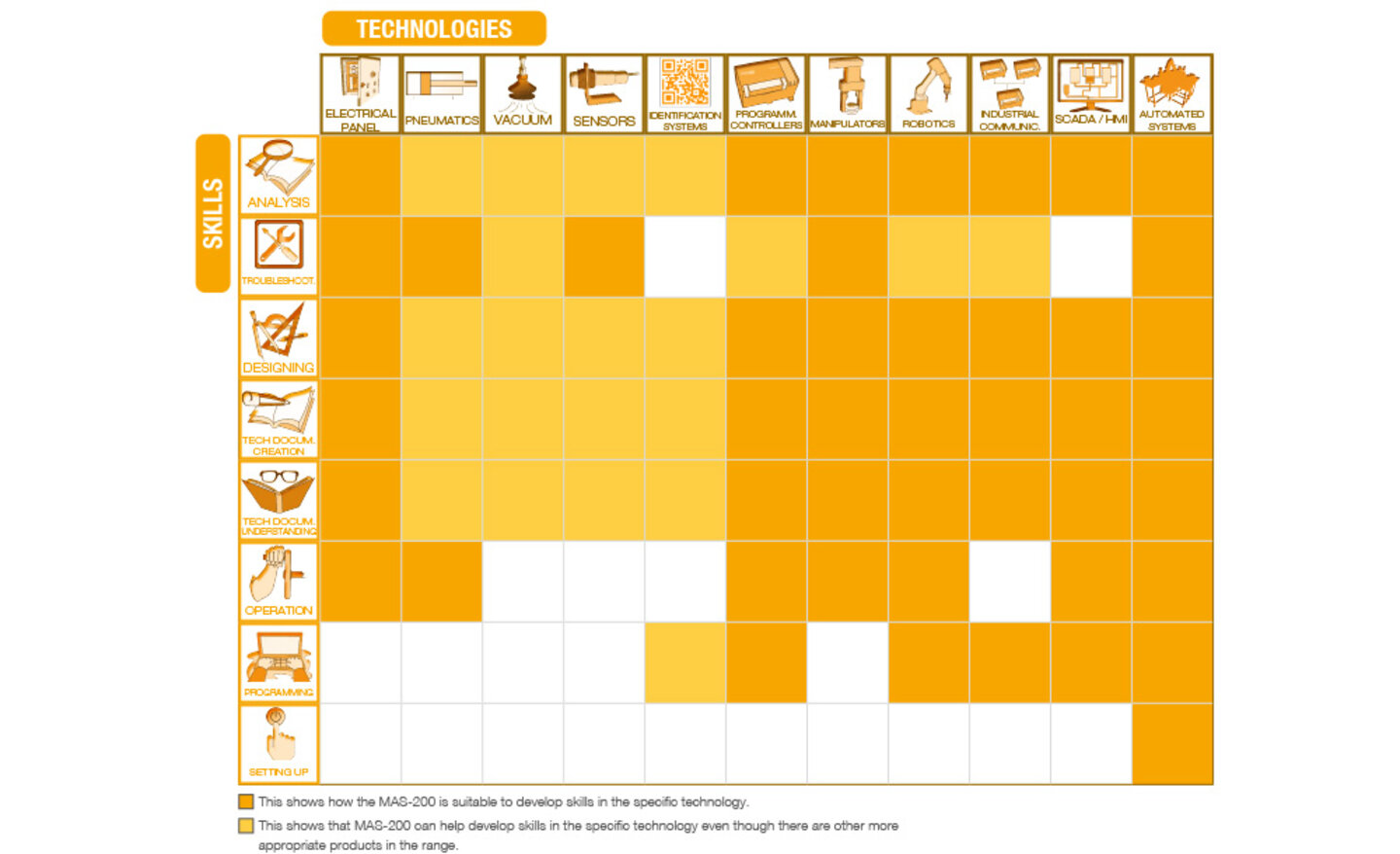

MAS-200 performs a real industrial assembly process, incorporating the technologies demanded by today's automated industry.

Modular System

The system is composed of five stations, each one dedicated to the feeding and assembly of different components: base, bearing, shaft and cover. The modularity of the MAS-200 system allows working with the stations in an autonomous or integrated way, adapting to different training needs.

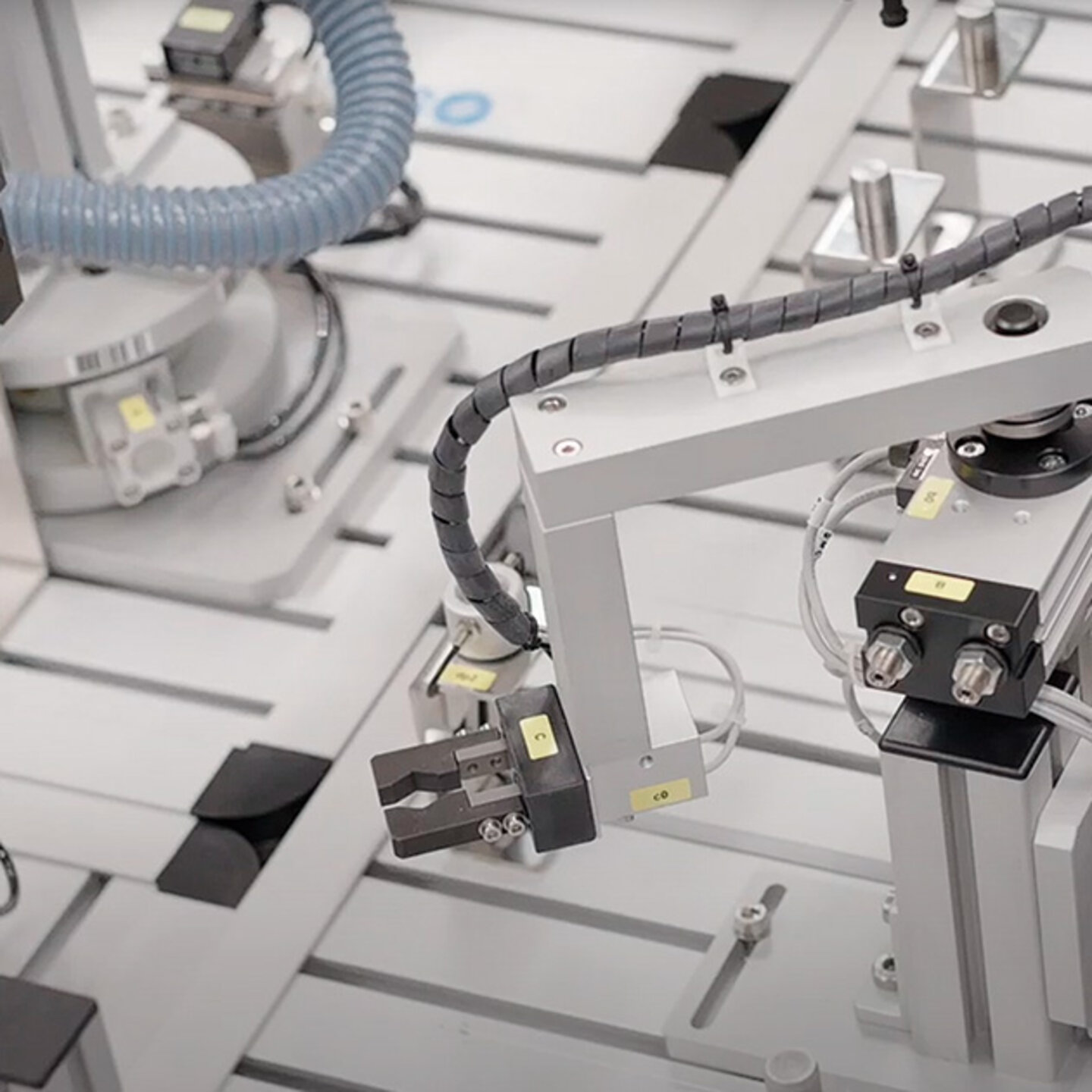

Pneumatic or robotic assembly

The station responsible for assembly can be adjusted according to the desired technology, whether pneumatic or robotic.

Flexibility in PLC and robot programming

MAS-200 includes the possibility of integrating different brands of programmable logic controllers (PLC) and robots, according to the user's needs.

Fault simulation

For complete training, the MAS-200 system offers the possibility of inducing non-destructive faults in the electrical circuit, allowing users to practice corrective maintenance. In addition, problems in assembly, installation and disturbances in the pneumatic circuit and PLC programming can be simulated, providing a comprehensive and realistic learning experience.