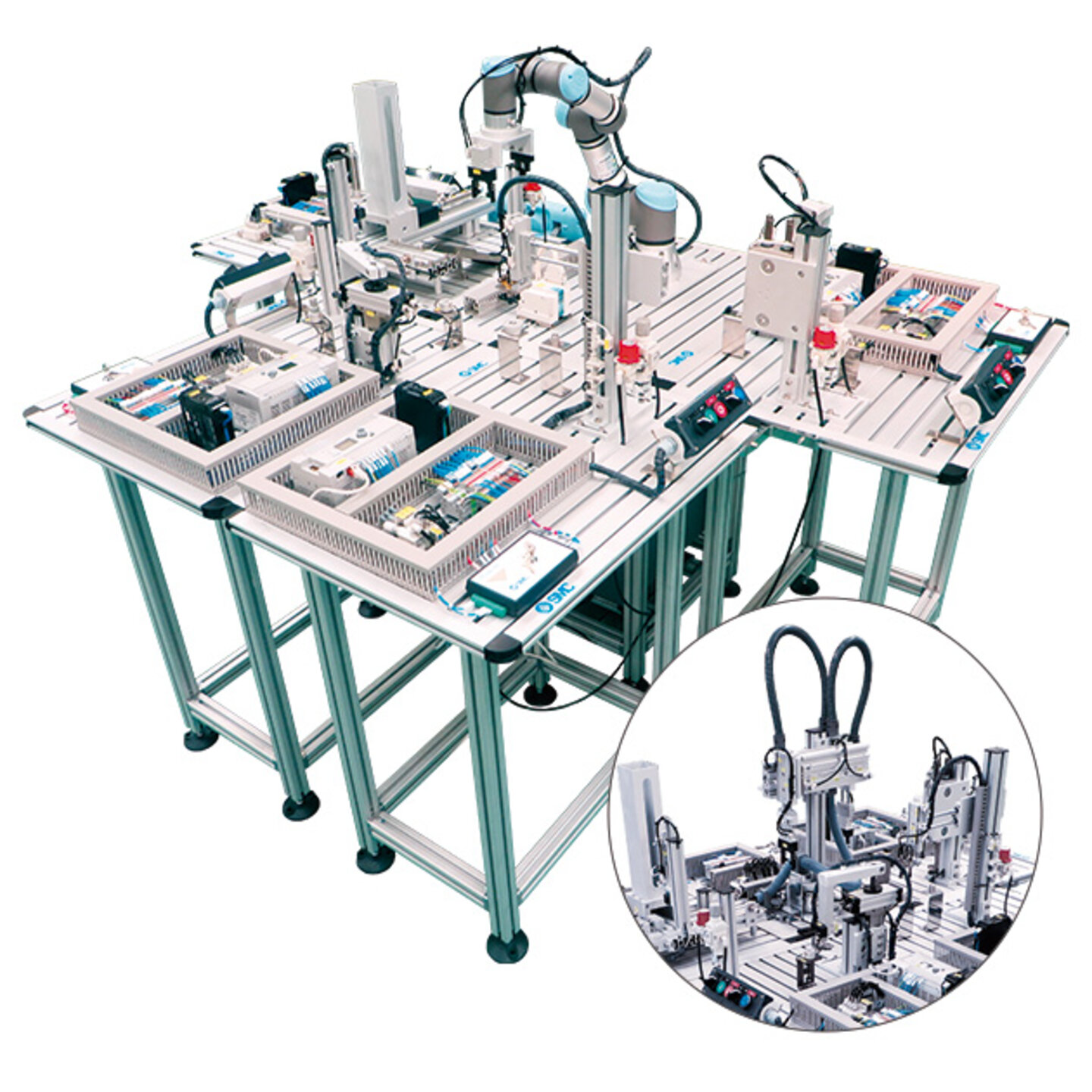

MAS-200 stations

Each of the MAS-200 system stations carries out a part of the process. The modular features of the equipment allow a vast range of options since the stations are completely autonomous, but can be assembled to form a complete manufacturing cell.