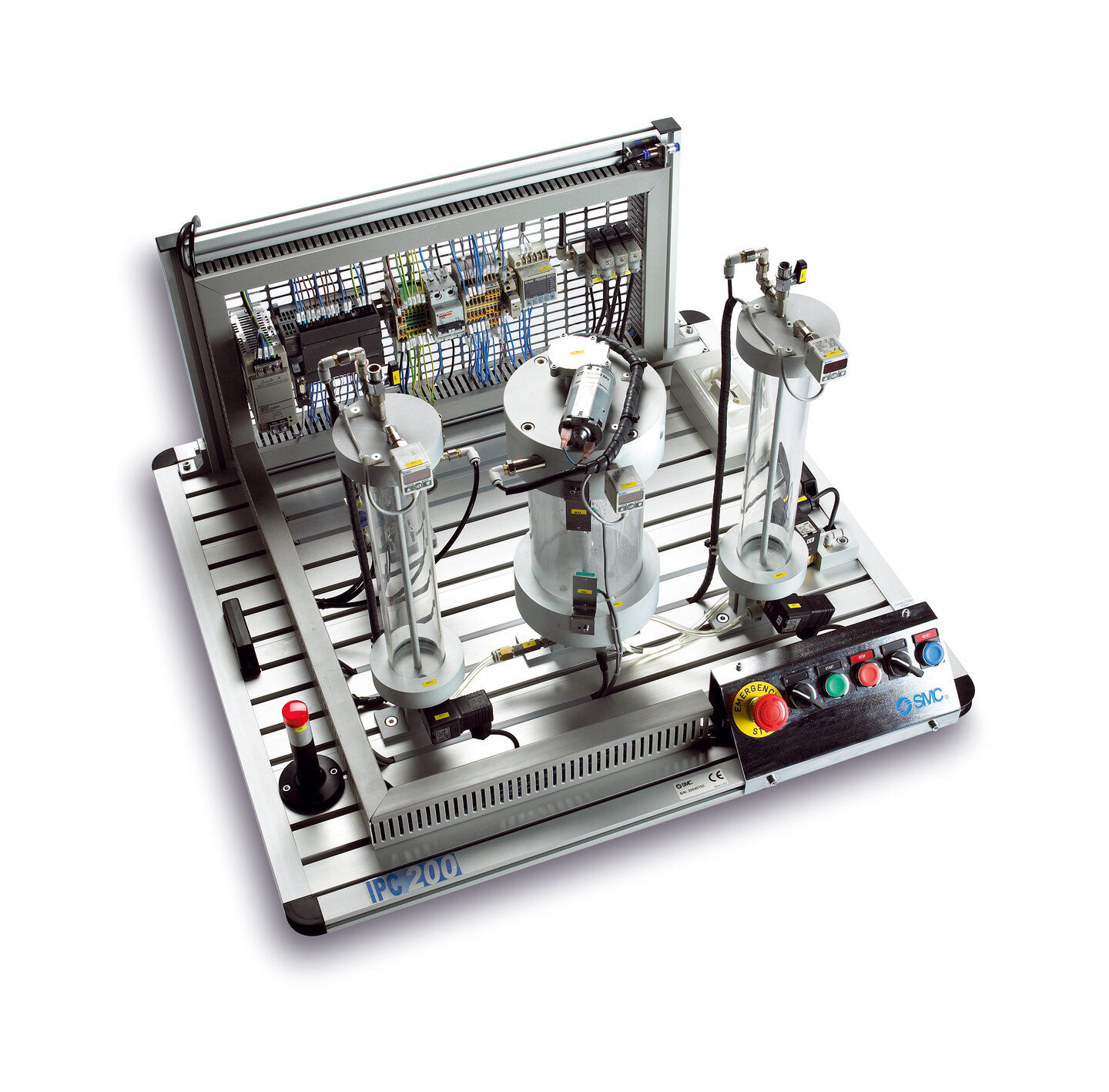

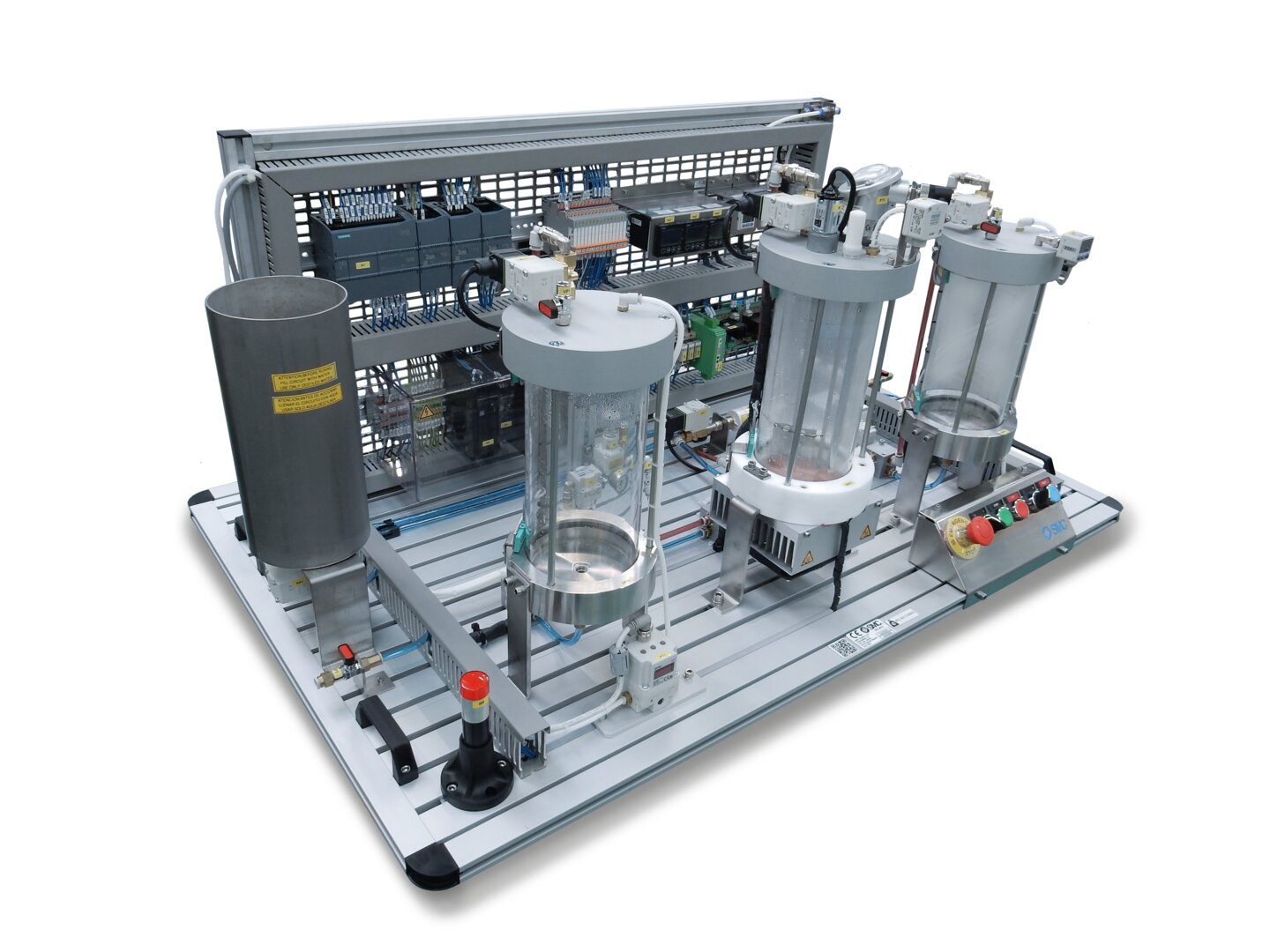

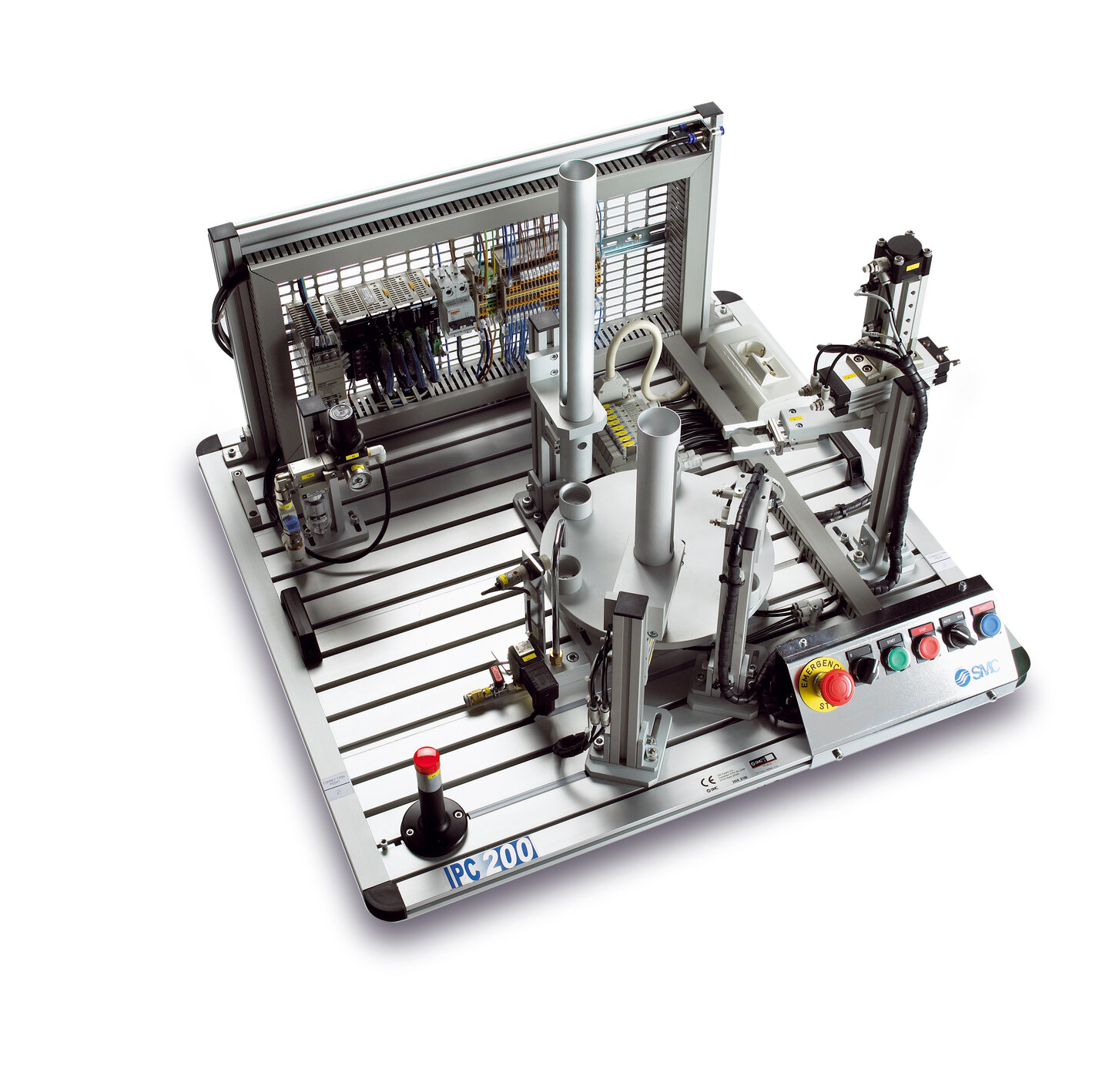

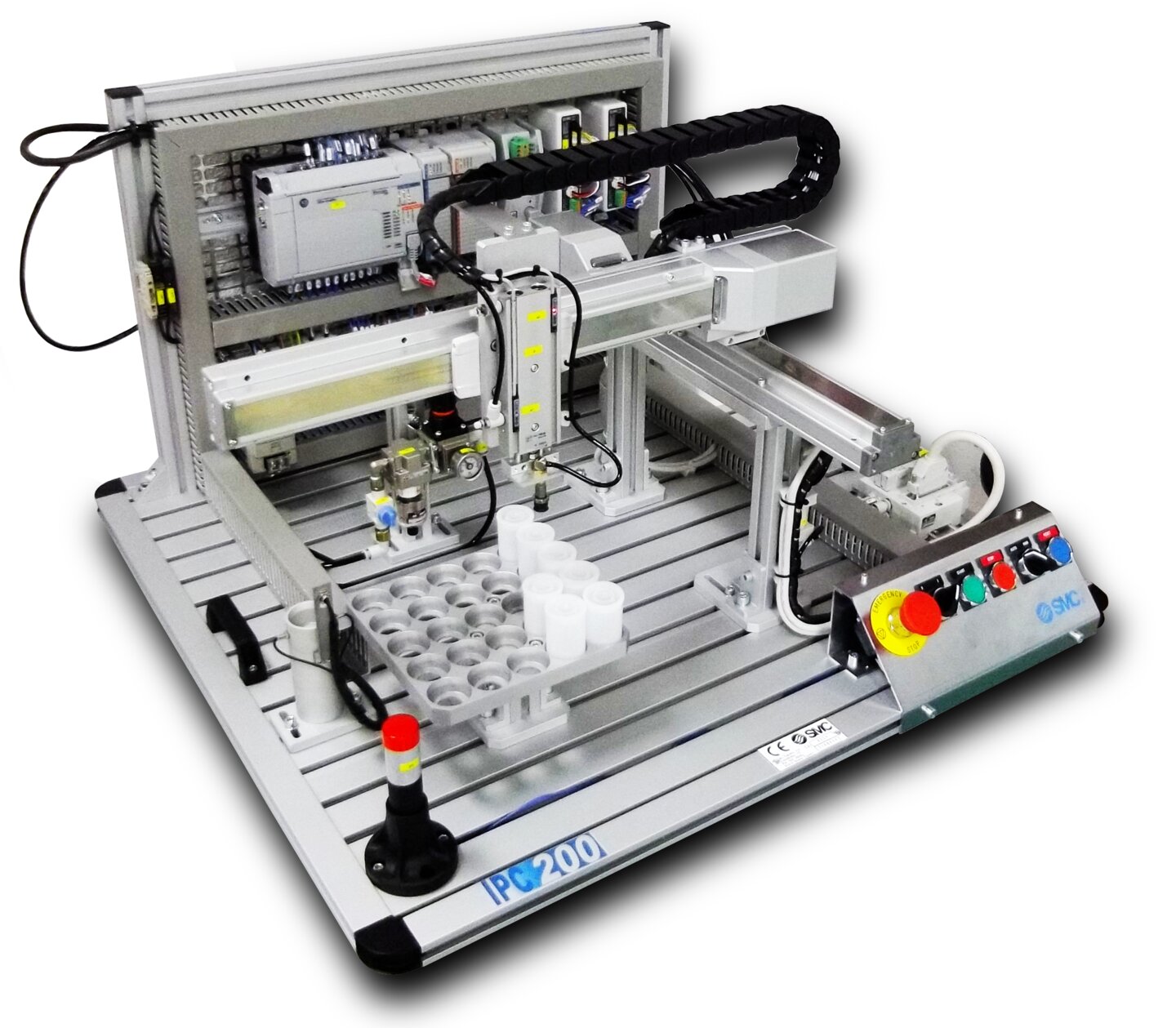

IPC-200 stations

IPC-200 is composed of three stations each of which carries out one part of the process. The modular features of the equipment allow a vast range of options since the stations are completely autonomous, but can be assembled to form a complete manufacturing cell.