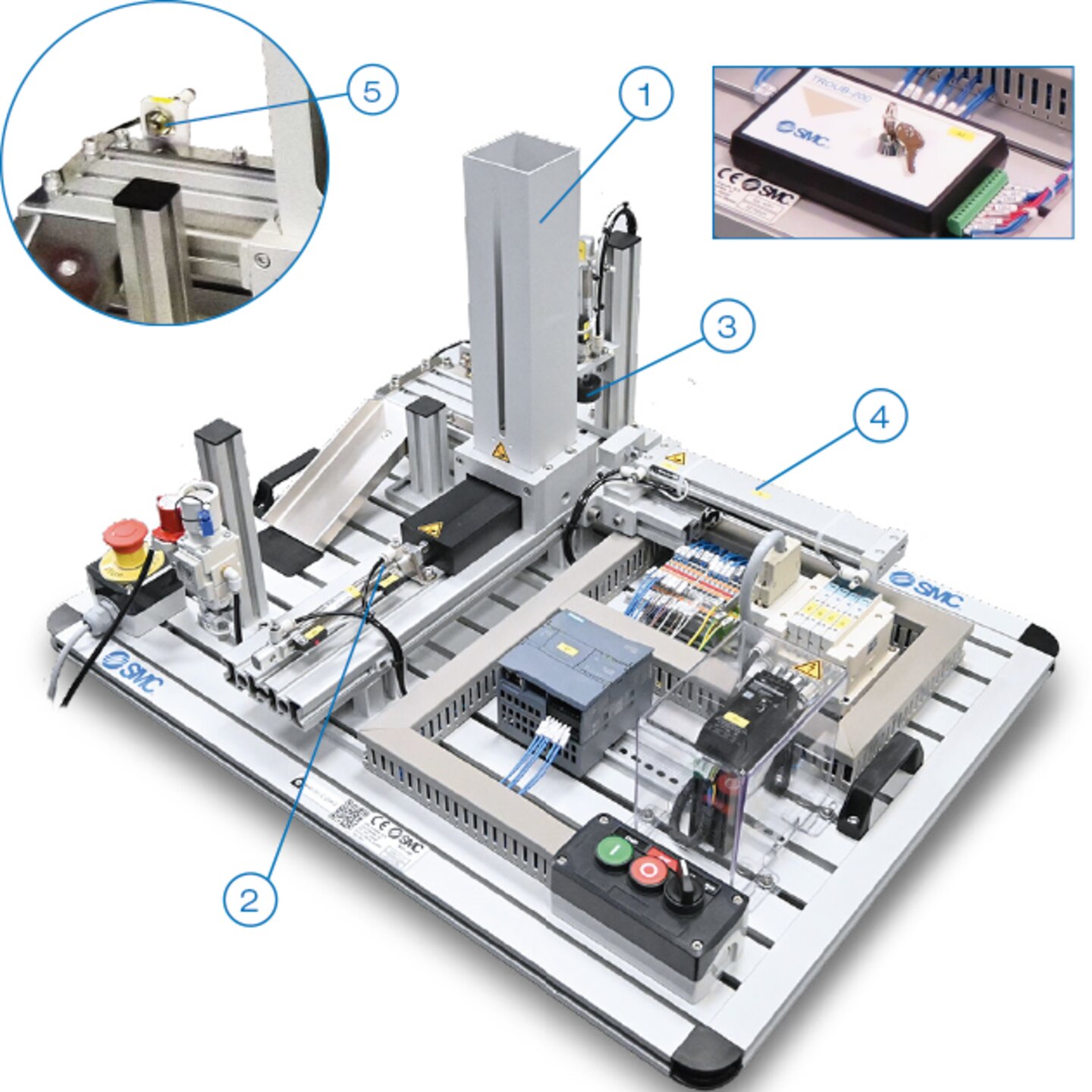

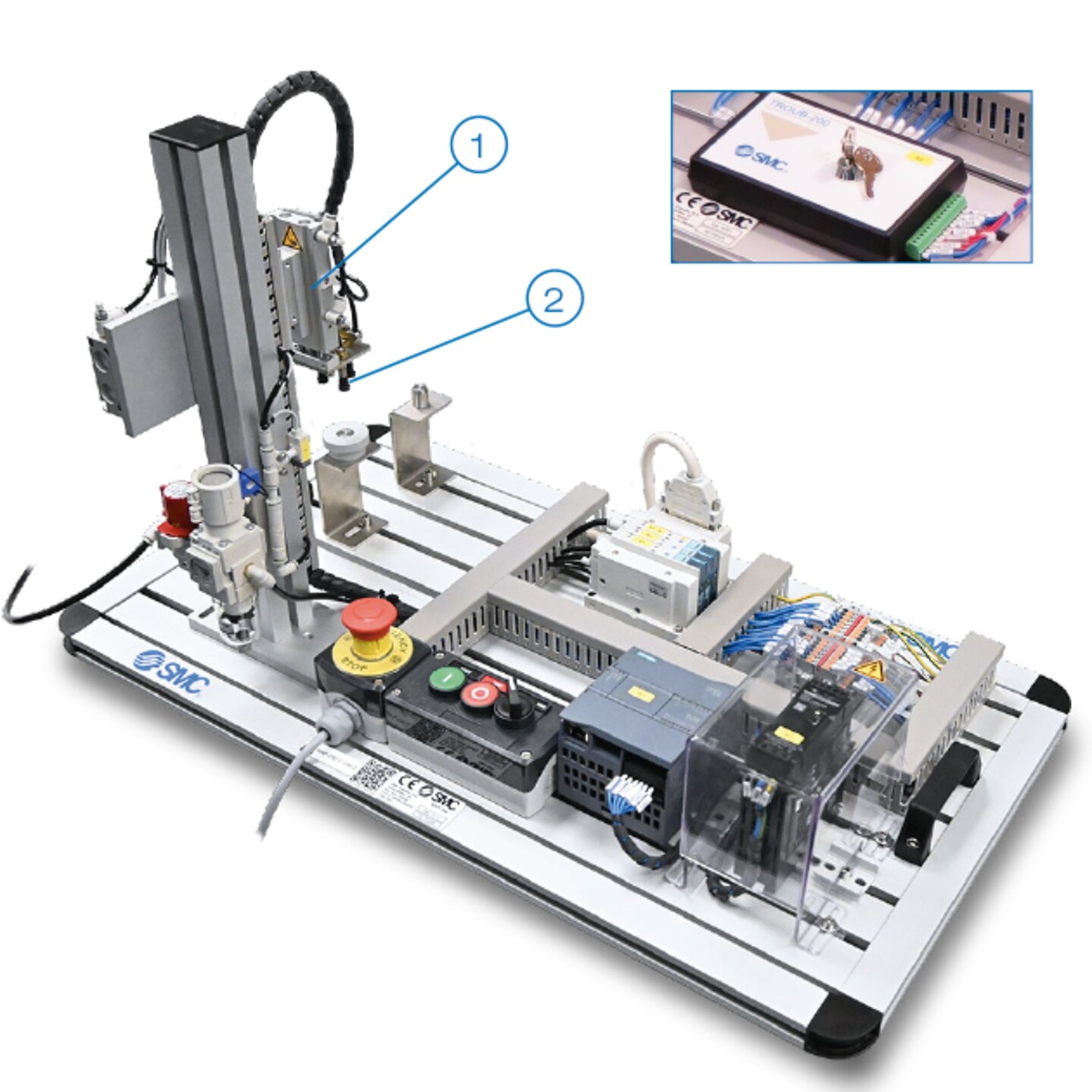

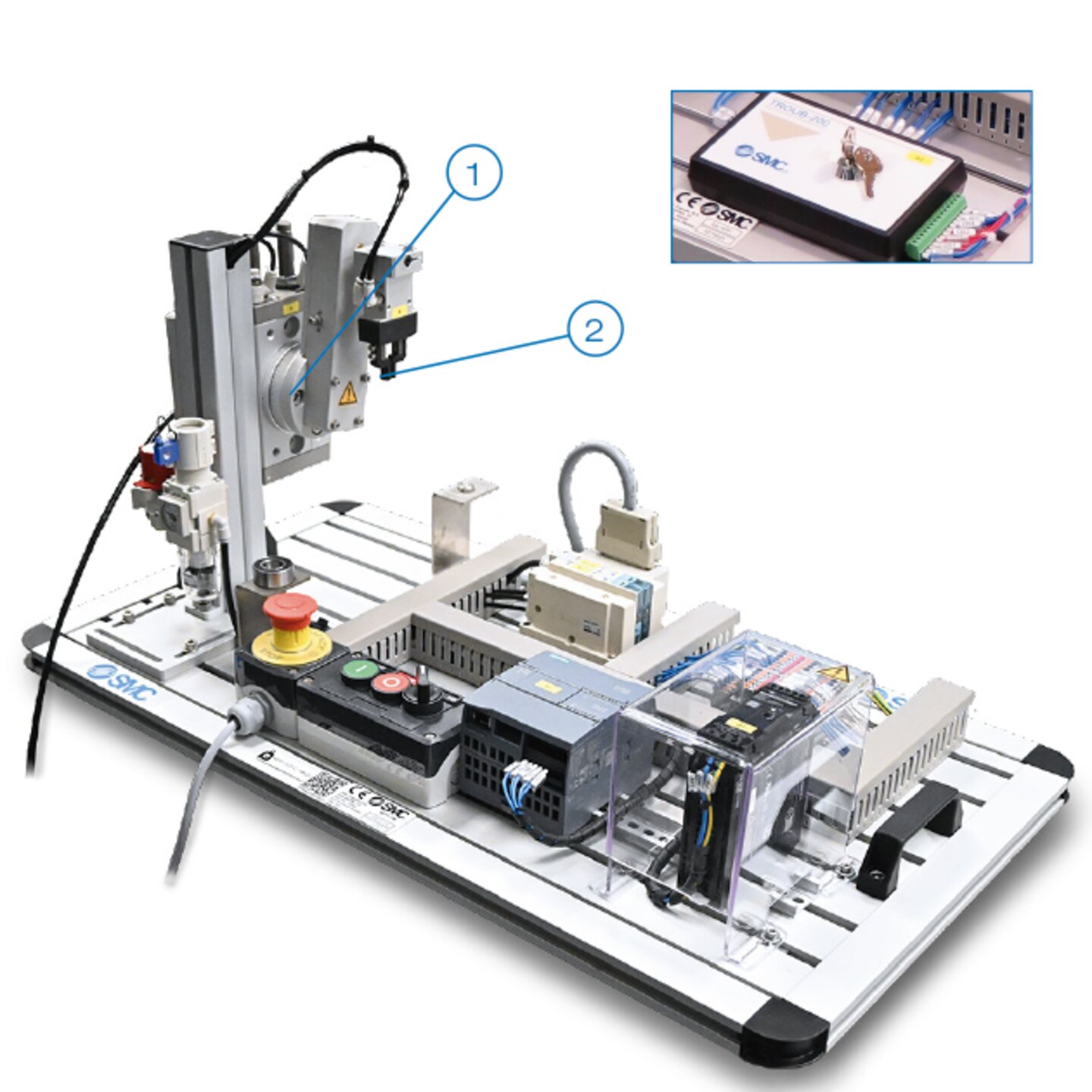

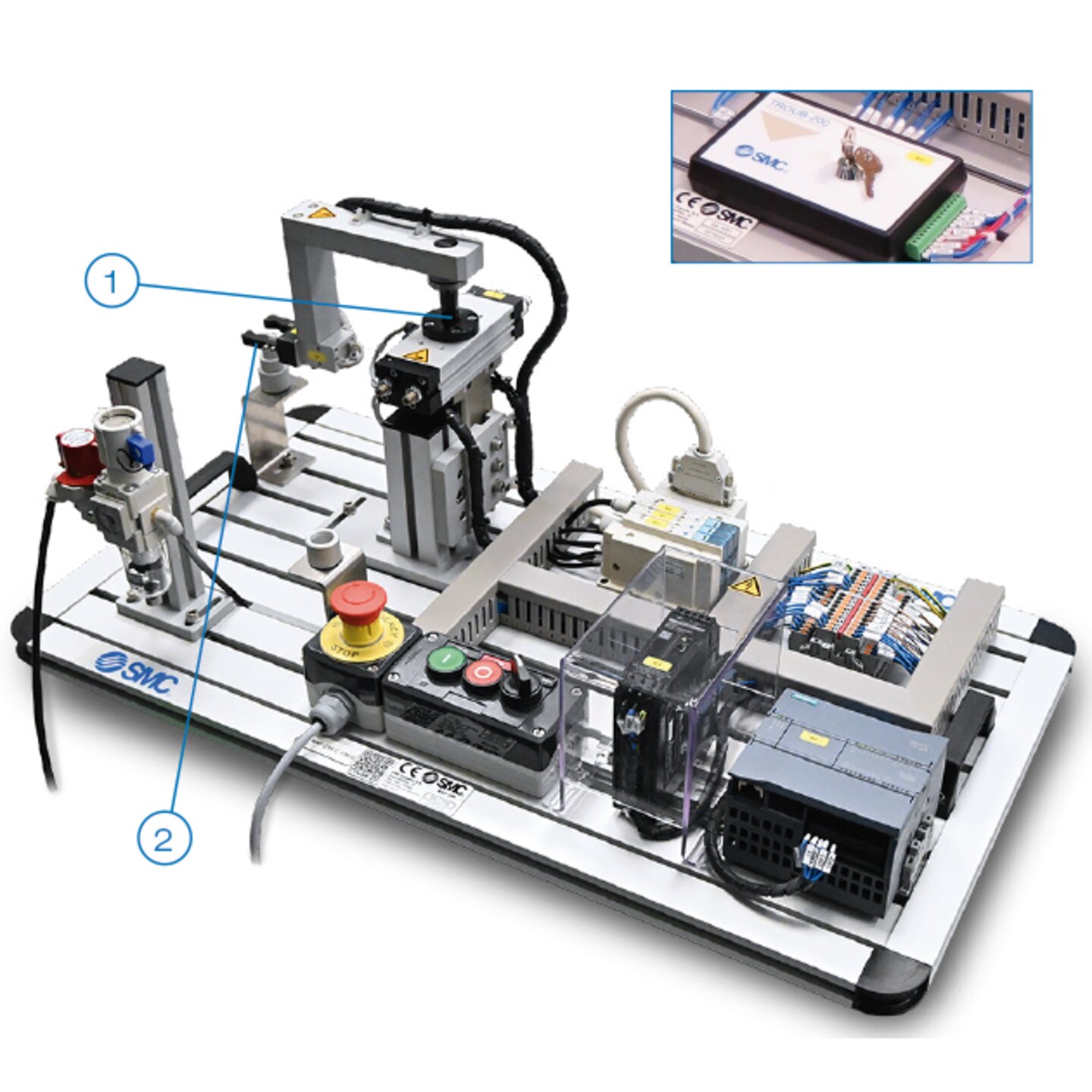

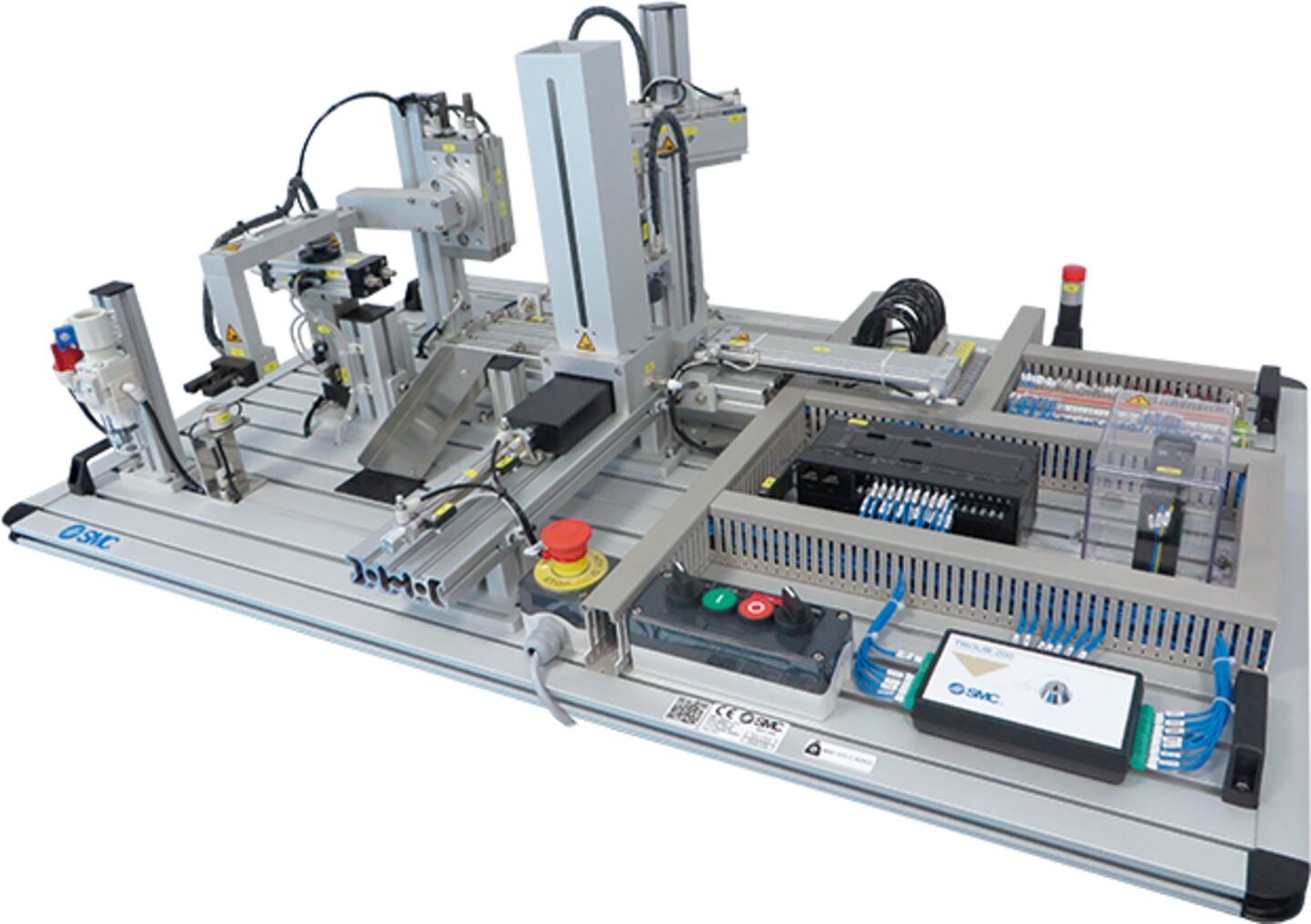

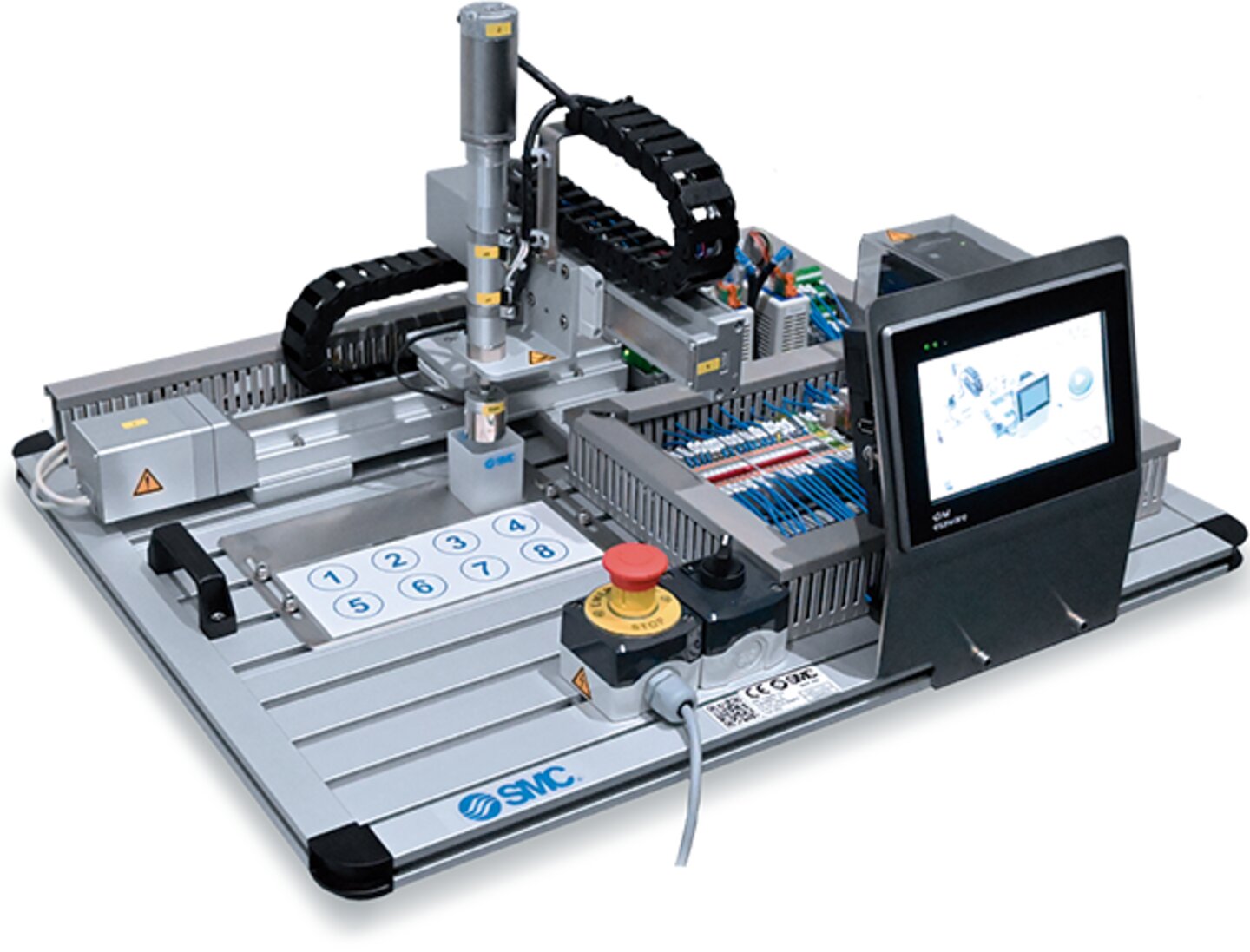

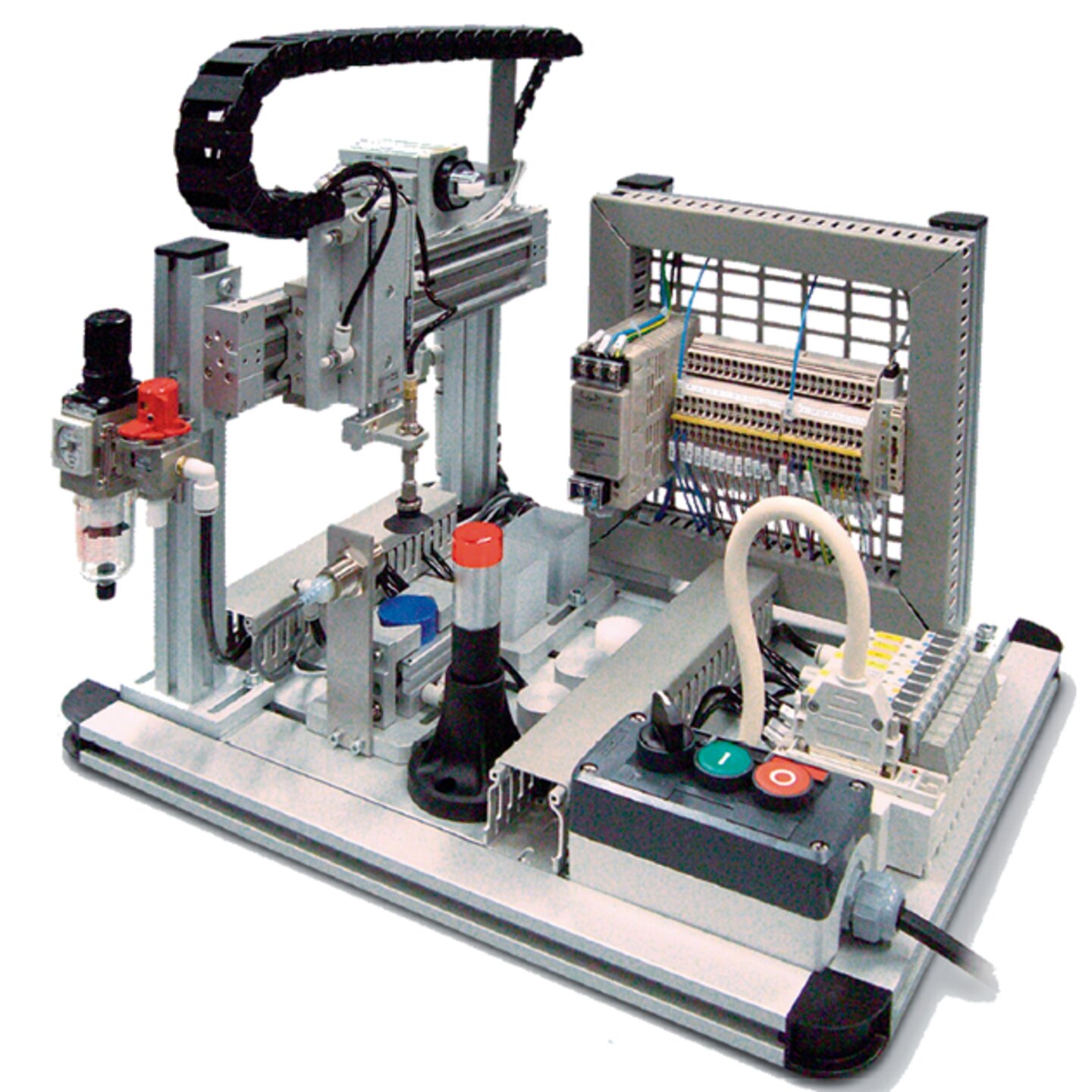

MAP-200 handling devices

The MAP-200 series consists of seven independent and different training systems: **MAP-201, MAP-202, MAP-203, MAP-204, MAP-205, MAP-206 y MAP-207**.

The MAP-200 series consists of seven independent and different training systems: **MAP-201, MAP-202, MAP-203, MAP-204, MAP-205, MAP-206 y MAP-207**.

Choose the option that best suits your needs and find out how to set up your references.