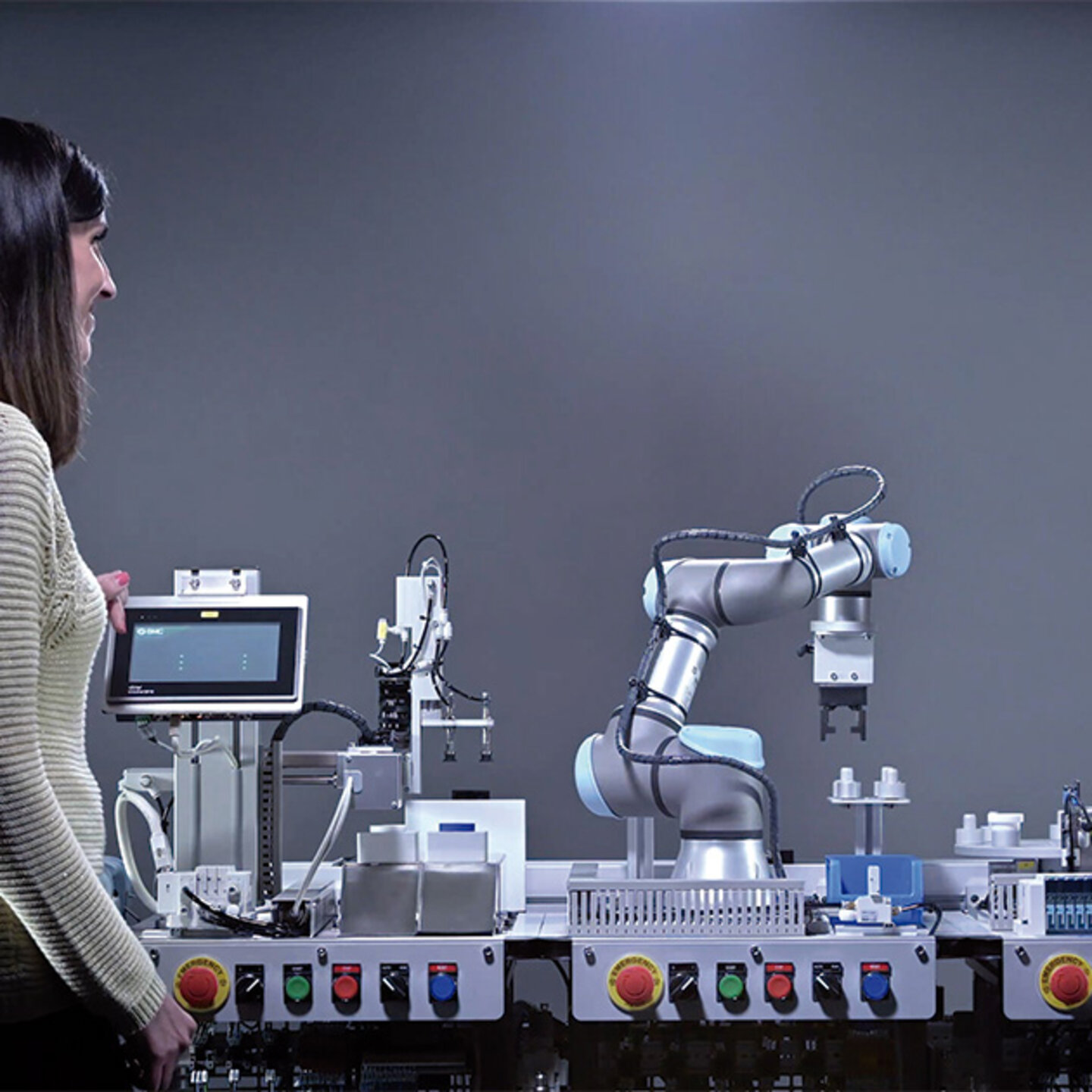

FAS-200 special edition with Industry 4.0 technologies

Training equipment in mechatronics with Industry 4.0 technologies. Develop the skills most in demand for 4.0 technologies and be prepared for the new challenges presented by Industry 4.0.

Training equipment in mechatronics with Industry 4.0 technologies. Develop the skills most in demand for 4.0 technologies and be prepared for the new challenges presented by Industry 4.0.

Training equipment in mechatronics with Industry 4.0 technologies. Develop the skills most in demand for 4.0 technologies and be prepared for the new challenges presented by Industry 4.0. FAS-200 SE I4.0 has been designed as compact equipment for the development of the skills most in demand in Industry 4.0 technologies affecting mechatronics and robotics.