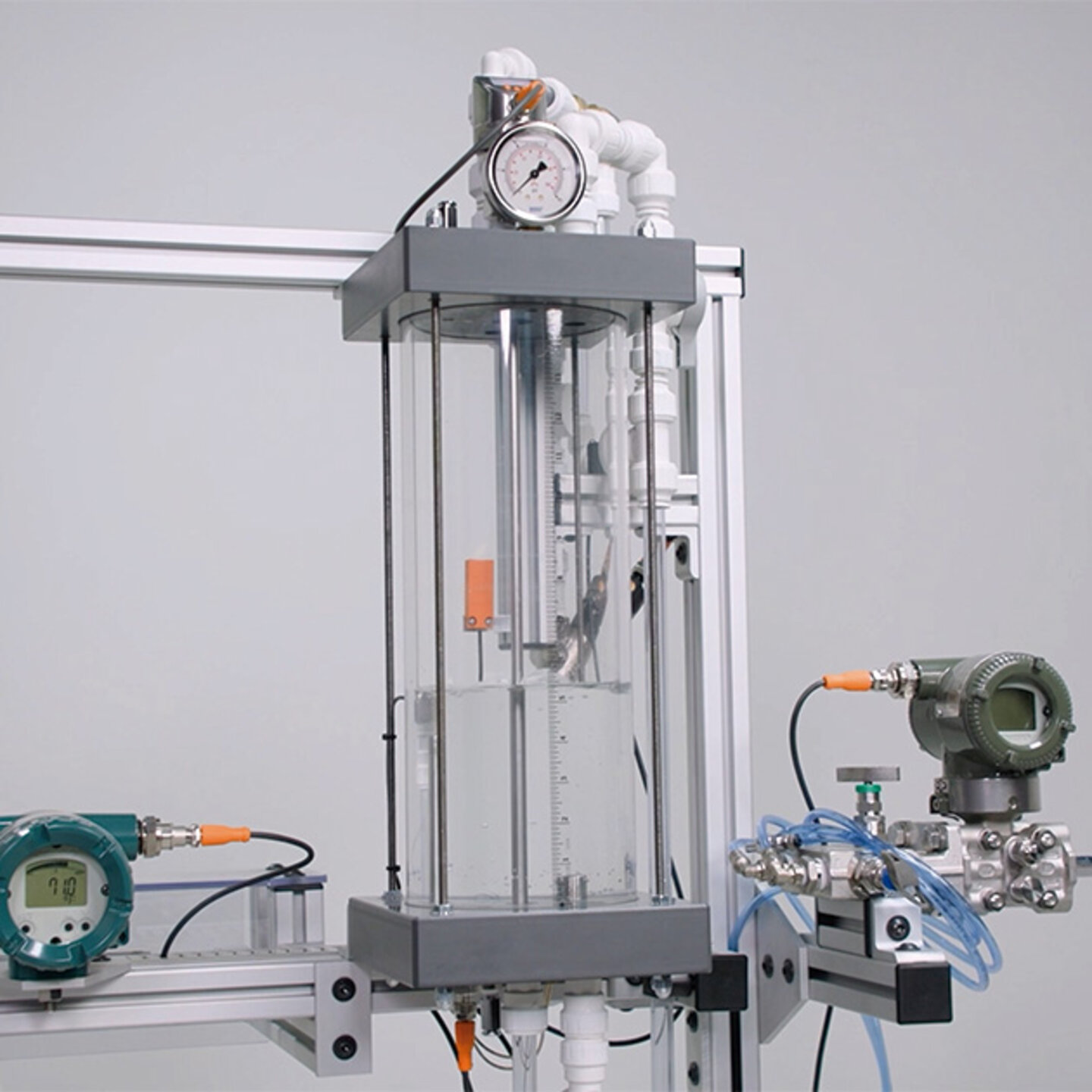

IPT-200 - Instrumentation and process control trainer

The Instrumentation and Process Control Trainer allows students performing hands-on experiments in Pressure, Flow and Level applications.

The Instrumentation and Process Control Trainer allows students performing hands-on experiments in Pressure, Flow and Level applications.

The Instrumentation and Process Control Trainer allows students performing hands-on experiments in Pressure, Flow and Level applications. The systems unique design allows rapid conversion between Pressure, Flow and Level experiments by adjusting the position of valves. All devices are pre-wired to terminal strips allowing for quick circuit modification. Activities in loop wiring, transmitter setup and loop tuning of PID parameters provide a thorough understanding of Process Control. The system is delivered in a mobile frame version and allows to include several add-ons.